Denim is a staple fabric known for its durability and timeless appeal. But how is denim made? Understanding the process behind its creation can help us appreciate the craftsmanship involved. From cotton harvesting to weaving and dyeing, here’s a step-by-step look at how denim is made.

Cotton Harvesting And Preparation

Denim starts with cotton, a natural fiber that is harvested from cotton plants. After harvesting, the cotton is cleaned and processed to remove seeds and impurities. This preparation ensures only the best fibers are used to create strong and durable denim fabric..

Spinning The Cotton Fibers

Once cleaned, the cotton fibers are spun into yarn. This process involves twisting the fibers together to form long threads, which are later used in weaving. High-quality yarn ensures the final denim fabric is both strong and comfortable to wear..

Indigo Dyeing Process

The iconic blue color of denim comes from indigo dyeing. The yarn is repeatedly dipped in indigo dye baths, allowing the fibers to absorb the signature blue hue. With each dip, the color deepens, giving denim its distinct look and characteristic fading pattern..

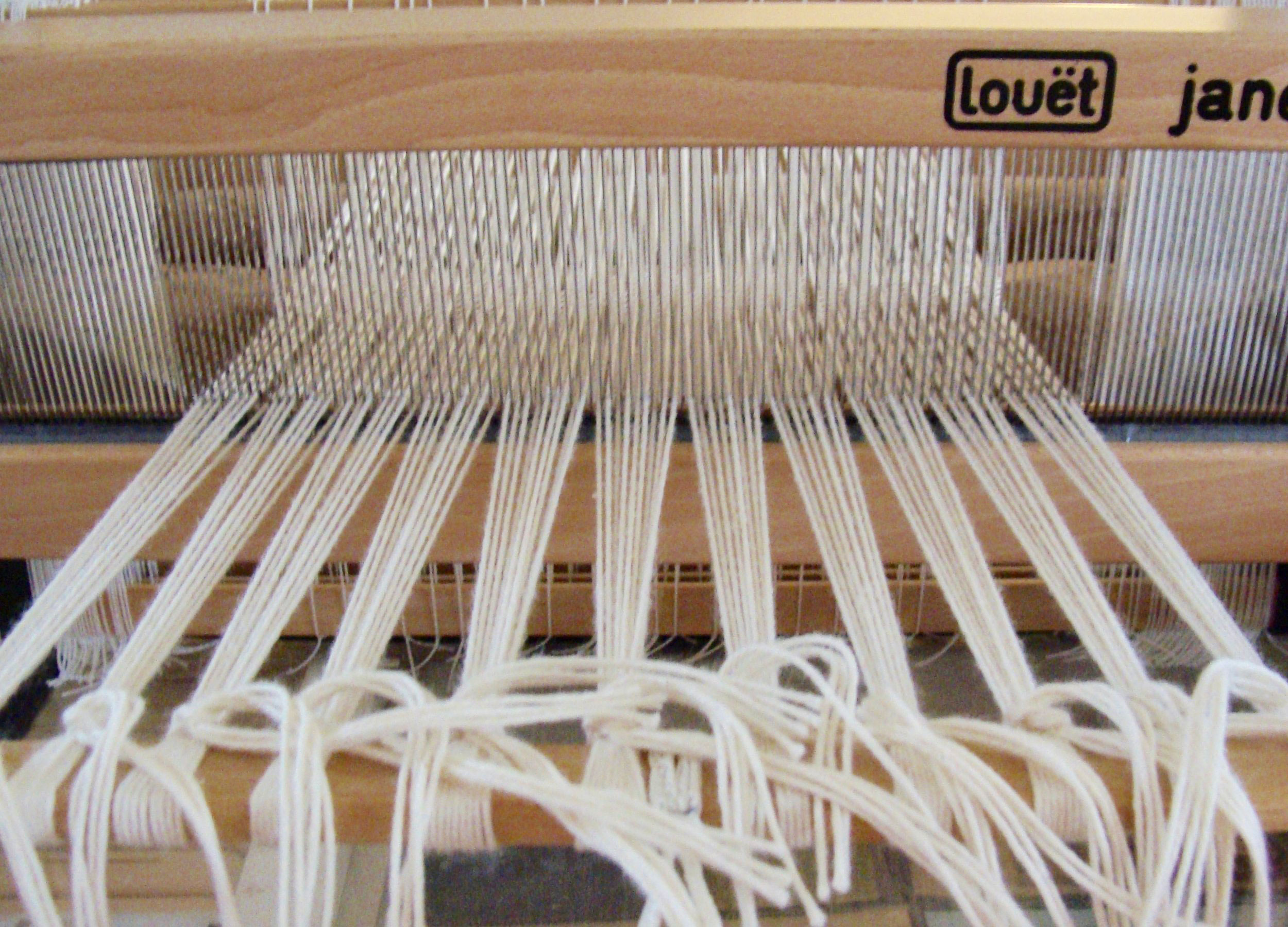

Warp And Weft Weaving

Denim fabric is created using a weaving process that interlaces warp (dyed) and weft (undyed) threads. The classic twill weave pattern gives denim its diagonal ribbing, contributing to its strength and flexibility for comfortable wear..

Pre-Shrinking And Finishing

Before being used for clothing, the denim fabric undergoes pre-shrinking and finishing treatments. This stage ensures the material won’t shrink excessively after washing. Additional treatments, such as stone washing or distressing, may be applied for different textures and effects..

Cutting And Sewing Into Garments

Once the denim fabric is ready, it is cut into patterns for jeans, jackets, and other apparel. Skilled workers sew the pieces together using durable stitches, reinforcing stress points with rivets to enhance longevity..

Washing And Distressing Techniques

After sewing, the denim garments are washed and treated to achieve different finishes. Techniques like acid washing, sandblasting, and fading create vintage or worn-in looks, making each piece unique..

Quality Control And Final Inspection

Before reaching consumers, denim garments go through rigorous quality control. Inspections ensure the fabric, stitching, and finishing meet industry standards, guaranteeing durable and stylish denim pieces for customers..

Denim production is a complex process that combines craftsmanship and technology. From cotton harvesting to the final product, each step ensures that denim remains a durable and stylish staple in fashion. Now that you know how denim is made, you can better appreciate the work behind your favorite pair of jeans.